bitSync wrote:I’m not suggesting anybody try this at home. But if anyone’s interested, here’s a little photo tour of my recent d8b hot rodding exploits. This all started with a quest for a totally silent d8b. I wanted to be able to have the d8b running in my tiny little studio and still be able to have open mics in close proximity to the d8b CPU/PSU. At first I thought I could get away with a quieter CPU fan and swapping out the hard drive for compact flash, but it was soon apparent that the AT PSU fan was the most egregious offender in the noise department. So, here’s what I did to my d8b #2.

This is not related to any noise issue, but I bought this board used and it had the original 32 Mbytes of RAM so I swapped that out for 256 Mbyte PC100 RAM.

The hard disk drive was removed and I imaged it to a compact flash card as described in a recent post.

In place of the hard disk I installed a silent 4 Gbyte compact flash (a Team TG004G2NCFJX 233X compact flash card in a Startech PLATEIDE2CF RTL adapter). I chose a rear-chassis-mounted CF adapter so I could get to and change out the Mackie OS boot media without unracking the CPU/PSU chassis and popping the top off.

The CPU fan was removed. Having tried a 50mm “quiet” fan I found the noise level still objectionable for close proximity open mics. I’m not really endorsing this modification because I can’t guarantee its long term performance, but I’ve run the board for tens of consecutive hours on several occasions, checking in on the CPU heat periodically, and it seems reasonably cool (for a CPU). In my opinion this technique requires that the chassis be sufficiently ventilated to cool by convection, that is, no sealed cover. I also upgraded the thermal paste with Arctic Silver 5 to promote the best possible heat transfer to the heat sink.

By far, the most challenging modification was installing a new Seasonic X-460 fanless ATX power supply in place of the roaring AT PSU.

This ATX modification required a variety of changes. First, I had to gut the entire CPU/PSU since there were going to be some chassis modifications which would be producing flying metal bits. Once empty, I had to slot the chassis sheet metal just a bit on the back to accommodate the IEC C14 power inlet socket on the ATX PSU. In order to get the chassis PSU mounting holes to line up with any holes on the PSU that notch in the chassis had to be ground out. I’m not certain but it appears that the AT and ATX mounting hole standards may be somewhat different? I got lucky because that rear face (every face) of the Seasonic X-460 is all holes.

Next, some changes to the component layout in the power supply cavity had to be made to accommodate the greater depth of the new ATX PSU. First, the transformer had to be moved to the vertical partition in the power supply cavity and further forward. The studs for the transformer mount had to be ground off the base of the chassis.

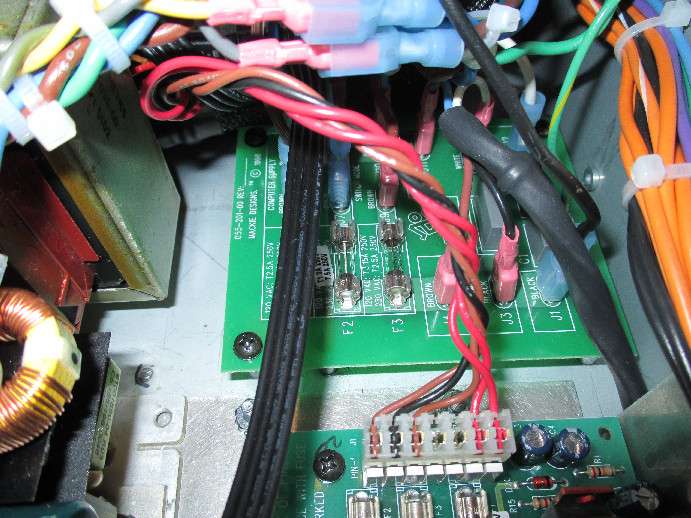

Also, the power distribution board had to be rotated 90 degrees for the same reason, to make more room for the greater depth of the ATX PSU. Only one of the original standoffs for the power distribution board was re-used to mount the board so 3 new standoffs had to be fabricated for the new orientation of the board’s screw holes. One of the original standoffs for the power distribution board also had to be ground off to make room for the ATX PSU.

Because the Seasonic X-460 ATX PSU is fanless, there is nothing to pull air from the openings in the front of the chassis across the power supply board so I resolved to leave the solid sheet metal cover off of the power supply cavity. Anybody sticking his hands in there just needs to know to not electrocute himself.

In addition to the relocation of the transformer and the rotation of the power distribution board, I had to fabricate and install a new rear panel sheet metal plate to accommodate a new NEMA 5-2 115vac power socket for the new AC power source and an IEC C14 standard inlet. Here is the view from the back panel.

The new ATX PSU plugs into the new switched outlet on the back of the chassis with a short standard IEC power cord and the chassis gets its 115vac mains through the new NEMA 5-2 switched socket.

Here is the view from inside the chassis. The chassis card cage assembly had to have a hole cut out of it where the new mounting plate and AC receptacles would go.

The original AT PSU supplied 115vac to the chassis front power switch. Since the ATX PSU has no such provision I had to fabricate a new AC wiring harness to connect the new rear panel AC receptacles to the power distribution board.

To make room for the AC receptacles and metal plate, the parallel port had to be removed from the parallel / mouse slot plate and in its place the DB25 connector for the console data (COM1 and COM2) was installed. So I lost the parallel port in the process but I’ve never had occasion to use it. If I ever want it I can put another DB25 connector on the back panel.

Finally, to accommodate the passive convection cooling requirements of the new rig I modified the chassis cover by cutting out several triangular sections of the sheet metal and installing in its place some perforated aluminum sheet metal that would allow the heat to escape and would keep the screwdrivers (but not the beer) out. This configuration really demands that an extra blank rack space be present above the d8b chassis to allow the heat to dissipate. For the sake of silence, I’m OK with that.

So, this was probably more than the average user is willing to invest in quieting the d8b CPU/PSU, but for me, the results were well worth the effort. My d8b #2 CPU/PSU is completely, utterly silent.

Cheers all.

Hi there!

Great tutorial!

I was wondering if its possible to give the computer a whole new motherboard with a faster processor and more ram.

A pentium 2 or a dual core processor, or mabybe a old motherboard from a laptop and built it inside the d8b.

When i put of the underplate is see a lot of free space between the aluminium coverplate and the underplate!